Description

Steel Grit is used extensively in blast rooms that are able to recycle abrasive media. It us used for descaling steel components and in the foundry industry to remove sand from components when castings have been subjected to ultra high temperatures and the sand is baked on to such an extent that steel shot is unable to remove it.

Steel Grit is made by crushing steel shot to angular particle subsequently tempered to different hardness to cater for different application, screened by size according to SAE Standard specification.

Chemical Composition:

| Carbon | 0.85-1.20% |

| Silicon | 0.45-1.50% |

| Manganese | 0.35-1.20% |

| Phosphorus | <0.05% |

| Sulfur | <0.05% |

Standard Hardness:

The steel grit is manufactured by crushing the fully hardened shot to granular grit form, screening and tempered to three different hardness range as follows :

GH = 63-67 HRc.

GL = 56-60 HRc.

GP = 40-50 HRc.

It is also available in tempering to various hardness range for special application.

Microstructure:

The microstructure of steel grit shall be uniform martensite, tempered to a degree consistent with the hardness range,with fine,well distributed carbides, if any.

Density:

The density of steel grit shall be not less than 7.4 g/cc.

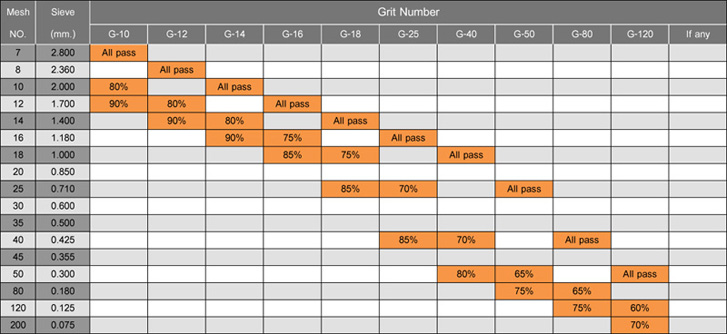

Size Distribution:

Grades Available:

| Grade | Selection Guide |

|---|---|

| GH12 | Blast Cleaning large to medium steel and iron castings |

| GH14 | Blast Cleaning large to medium steel and iron castings |

| GH16 | Blast Cleaning large to medium steel and iron castings |

| GH18 | Granite Cutting, Blast Cleaning Castings, Cleaning Structural Steel |

| GH25 | Granite Cutting, Blast Cleaning Castings, Cleaning Structural Steel |

| GH40 | Granite Cutting, Blast Cleaning Castings, Cleaning Structural Steel |

| GH50 | Cleaning Non-ferrous Casting and Structural Steels |

| GH80 | Cleaning Non-ferrous Casting and Structural Steels |

Pack Size:

25kg Bags