Description

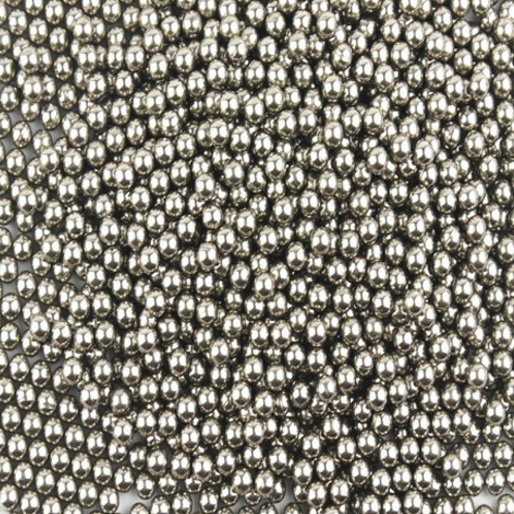

The high density of Stainless Steel Shot along with it not shattering on impact, also delivers very high impact energies to the work piece, resulting in faster cleaning rates.

Stainless Steel Shot is used for applications where residue on the blasted component is undesirable and/or when a very bright surface finish is required. Stainless Steel Shot will not rust or leave any ferrous residue or staining on the work piece. Stainless Steel Shot is widely used on magnesium, aluminium, nickel and chromium based alloy components and other nonferrous parts.

Industry users include: Aerospace/Aviation, Automotive, Consumer Goods Manufacturing, Foundry/Die Cast and OEM Subcontractors.

Typical applications include: Peening critical aircraft and automotive components; surface preparation of stainless steel and non ferrous components; removal of ceramic residue from investment castings and deburring and surface finishing of aluminium die castings.

Pack Size:

25kg Bags